KONMOS make electric vehicle and hybrid vehicle motors are designed and developed including but not limited to two wheeler, three wheeler, tractor, mini truck, mini bus, rickshaw and load carriers. Small and medium rating motors are designed considering the need of local and global industry. Wide range of efficient and cost effective solutions for various electric vehicle type ensures the optimized performance. Indigenous design, development, testing and manufacturing of electric vehicle and hybrid vehicle motors contributes to ATMANIRBHAR BHARAT ABHIYAAN and helps to make India as a preferred destination for production of automobile.

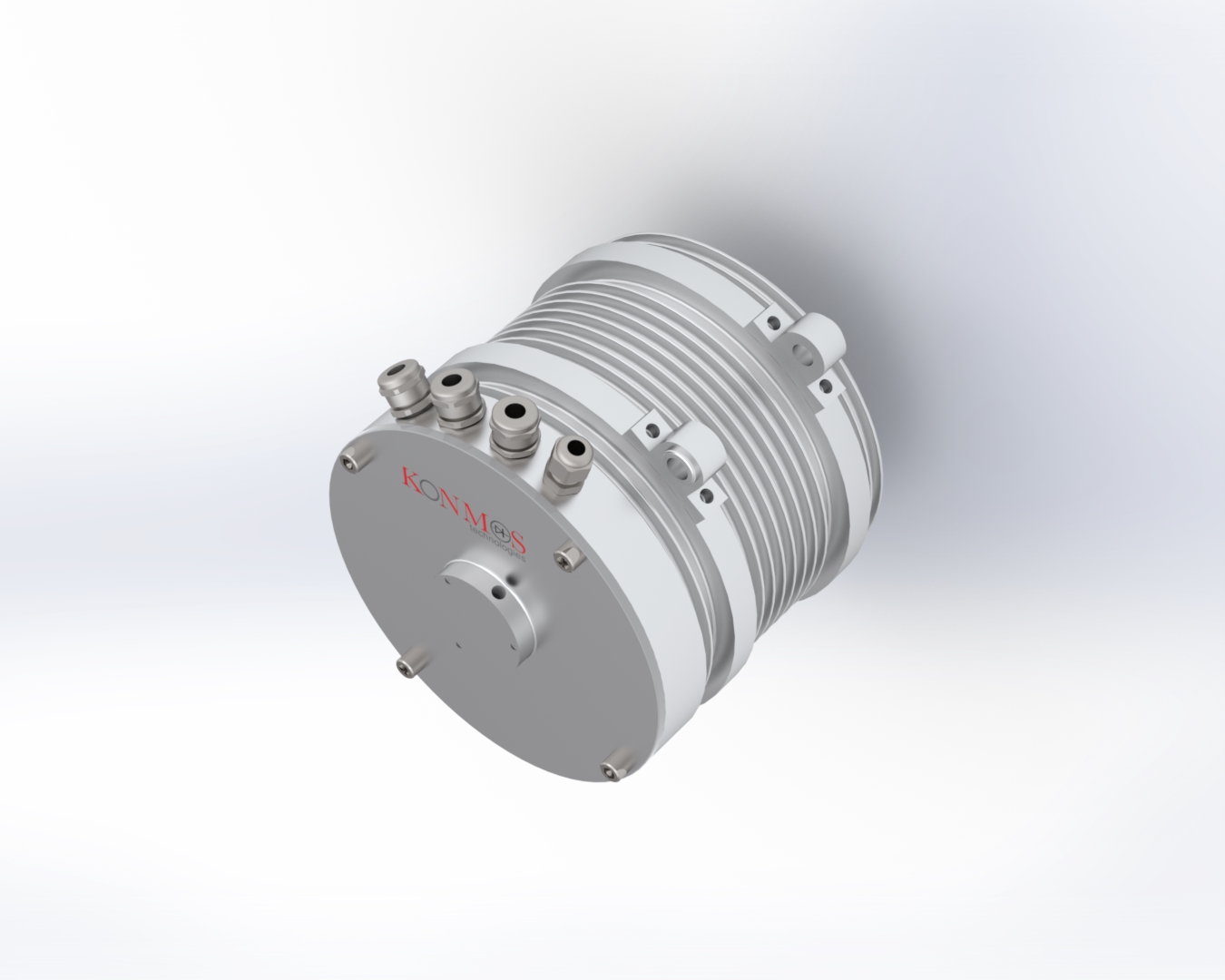

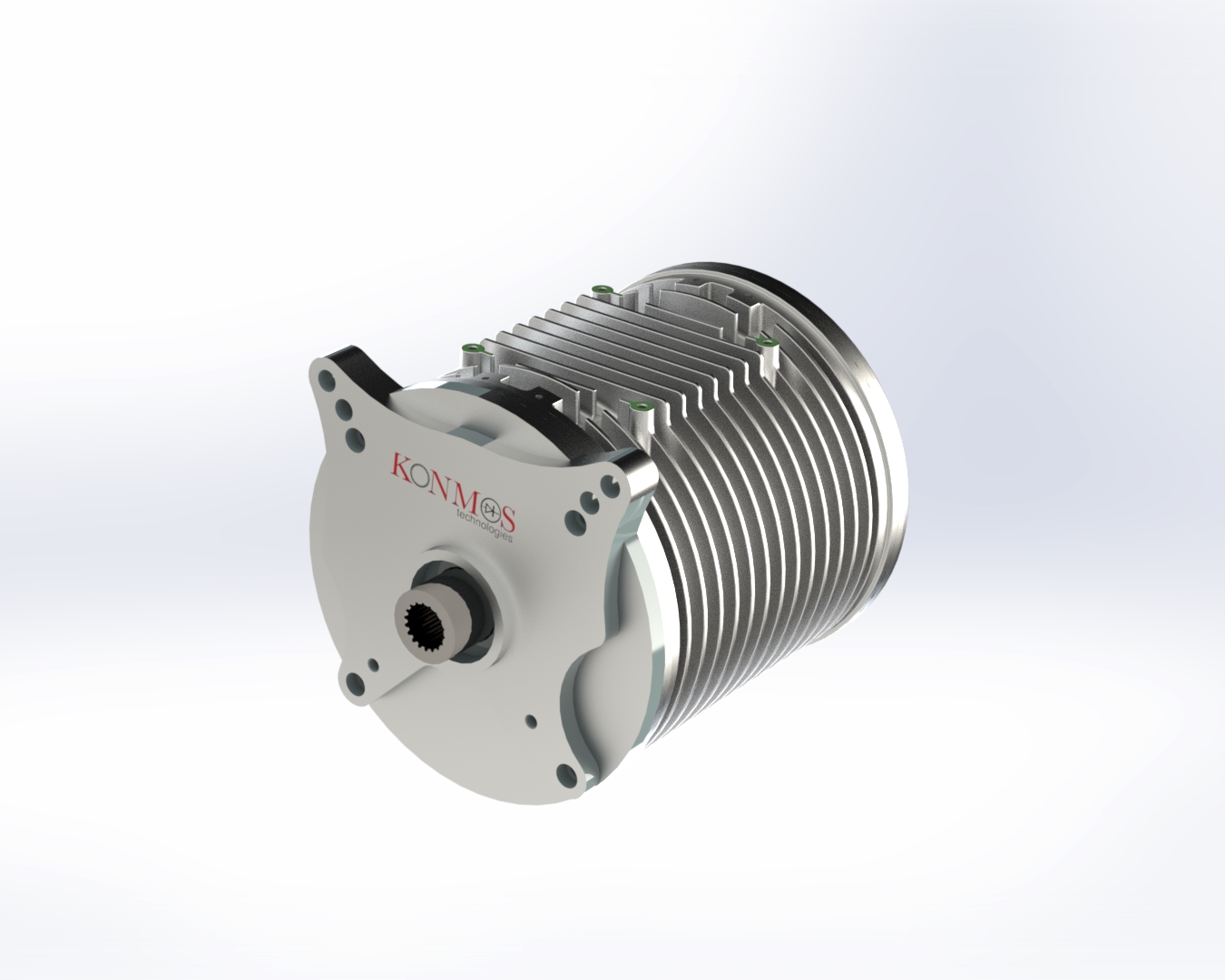

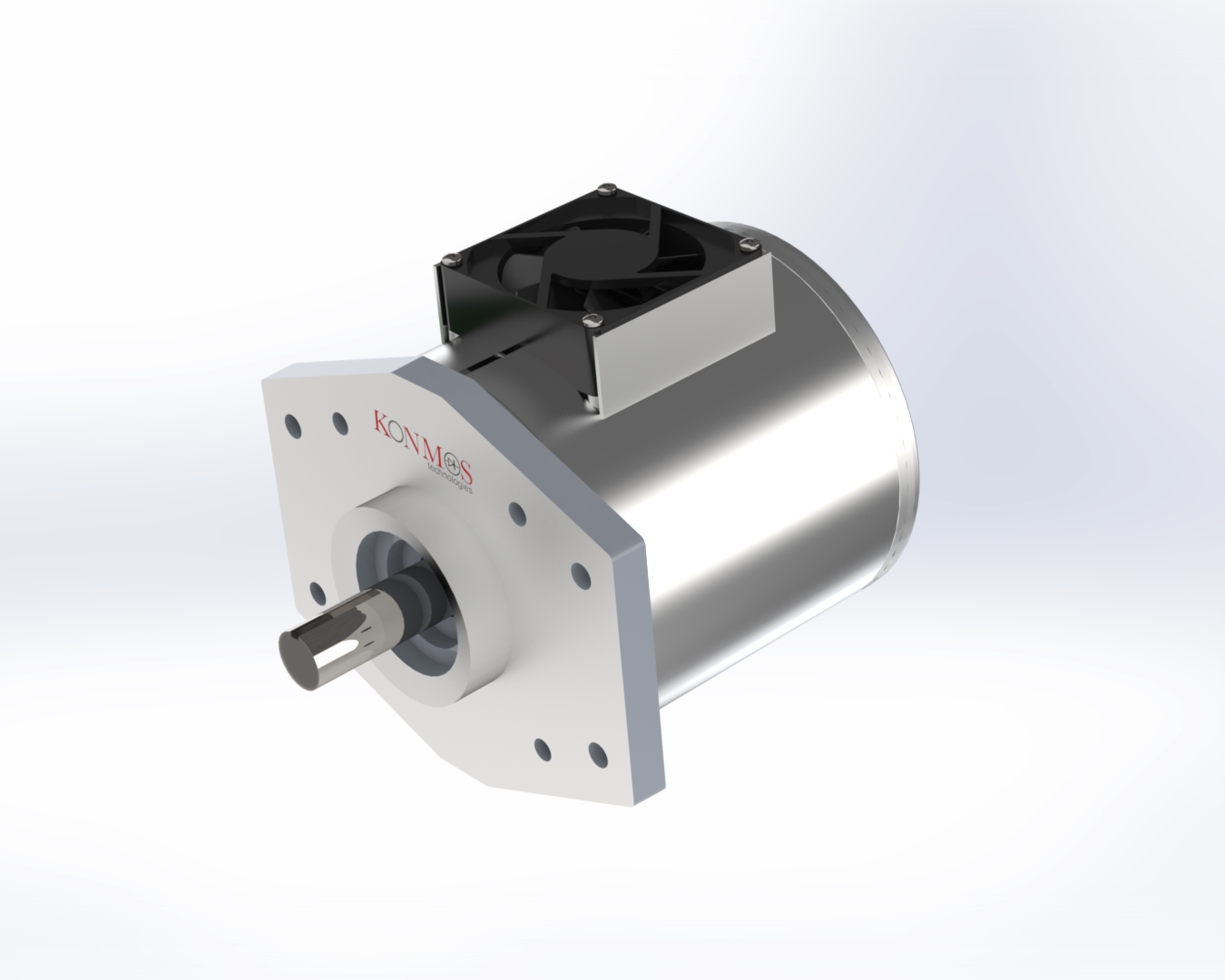

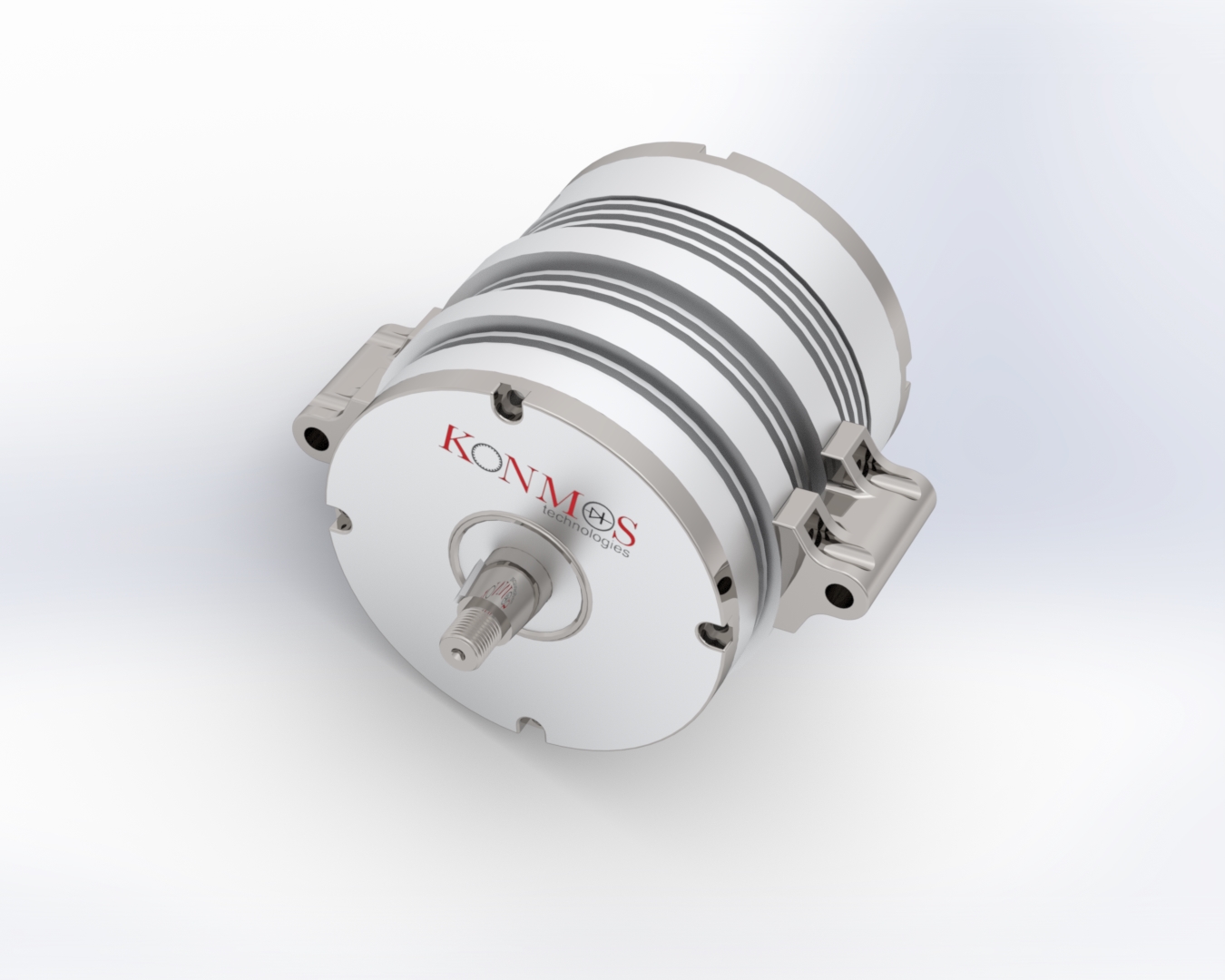

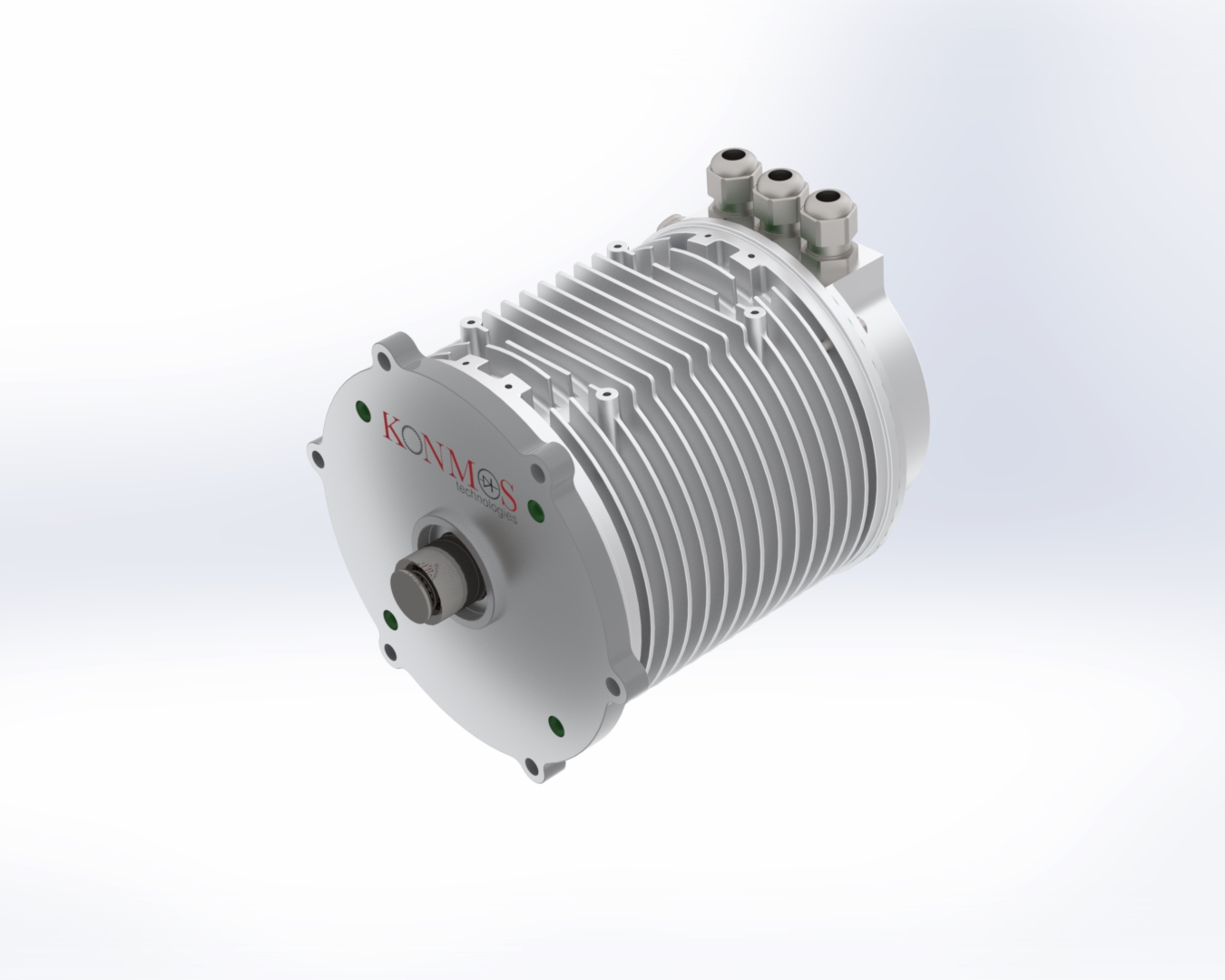

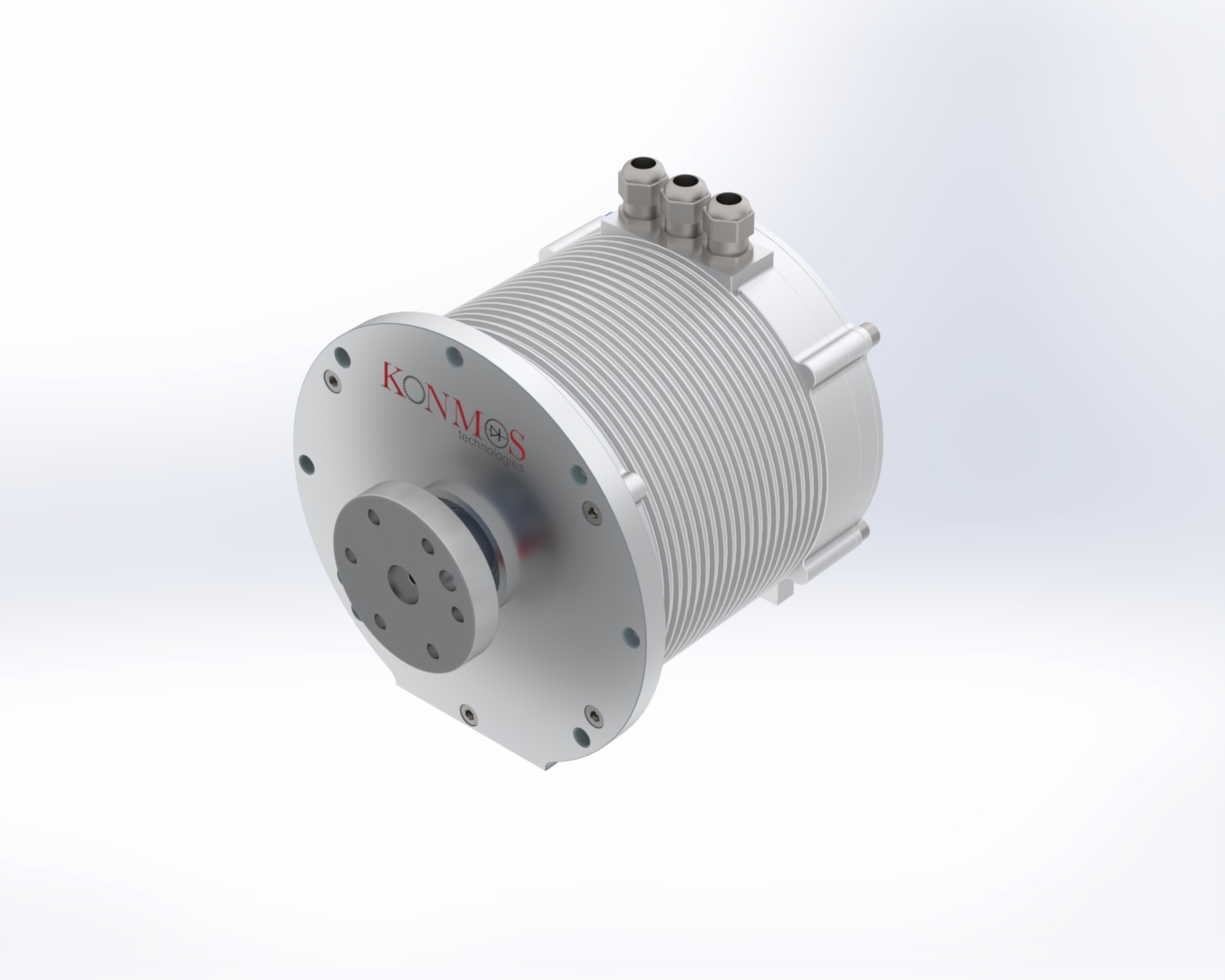

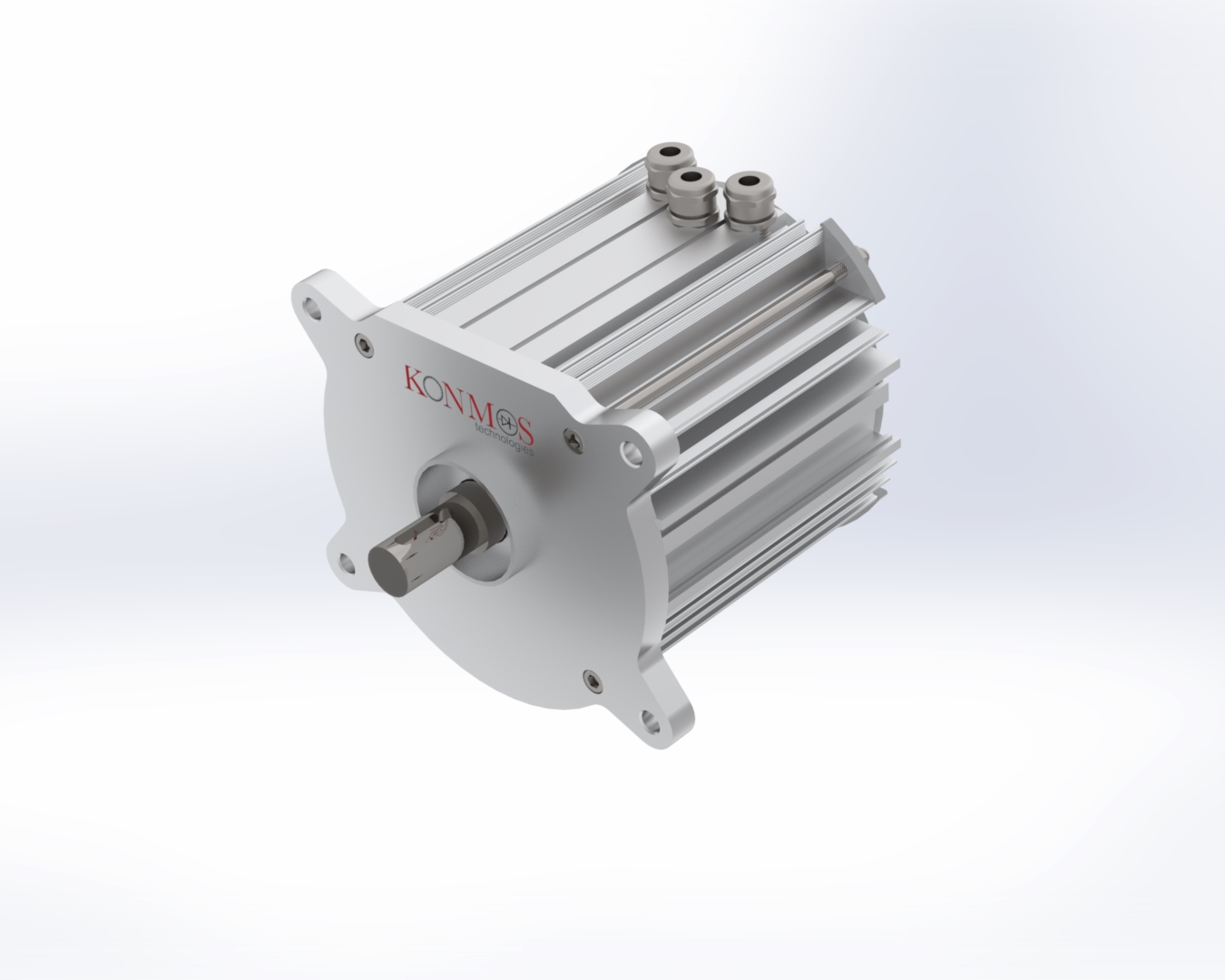

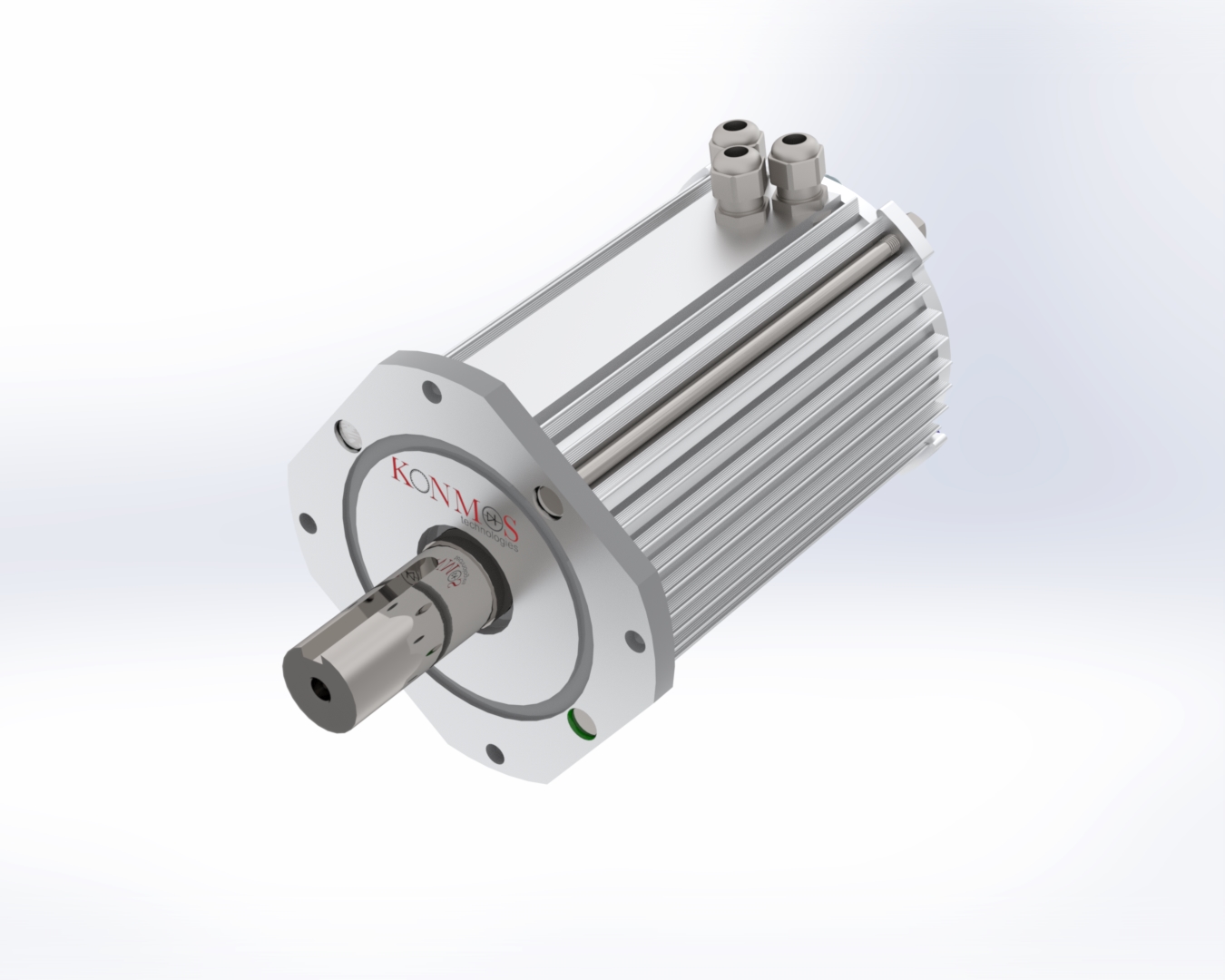

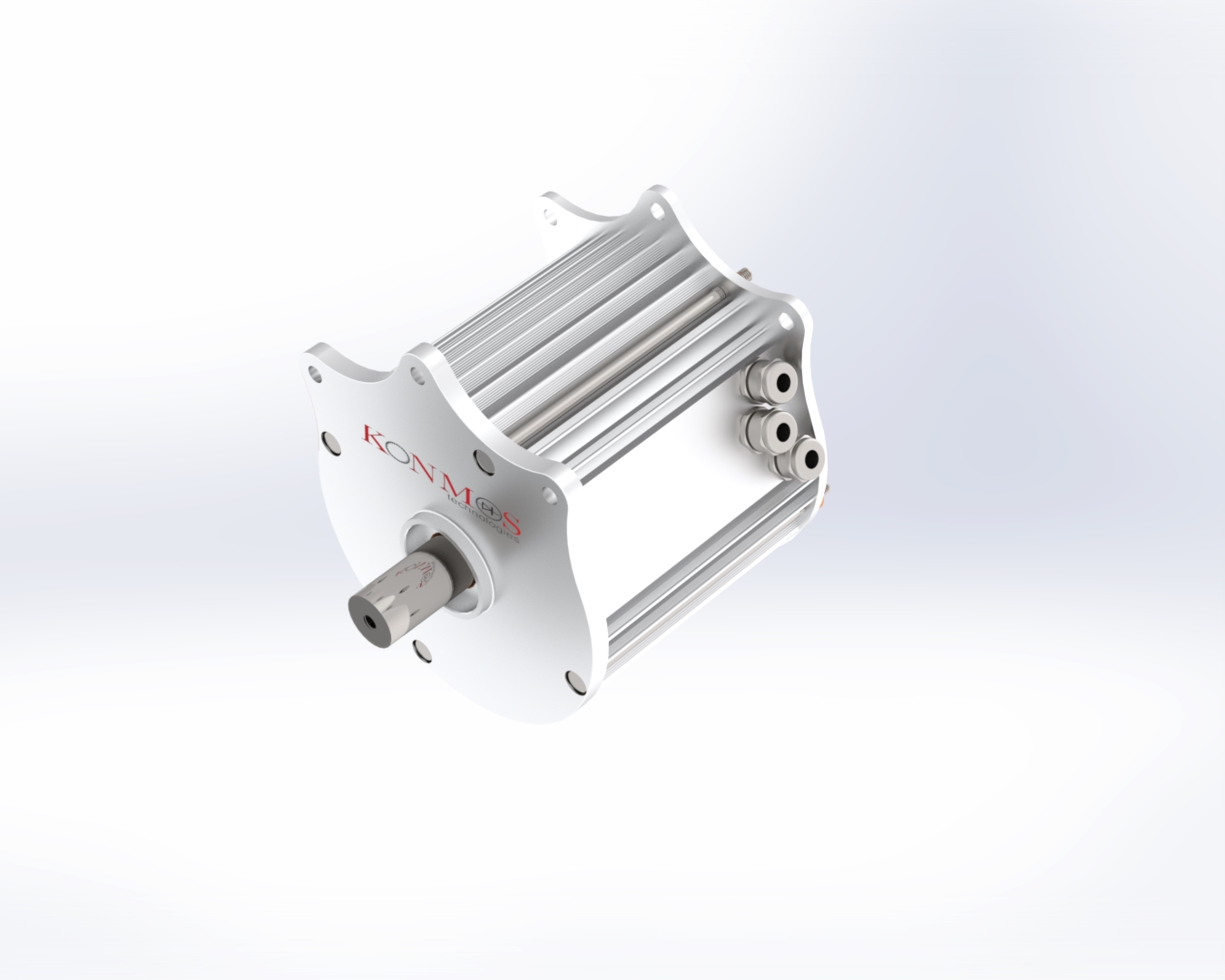

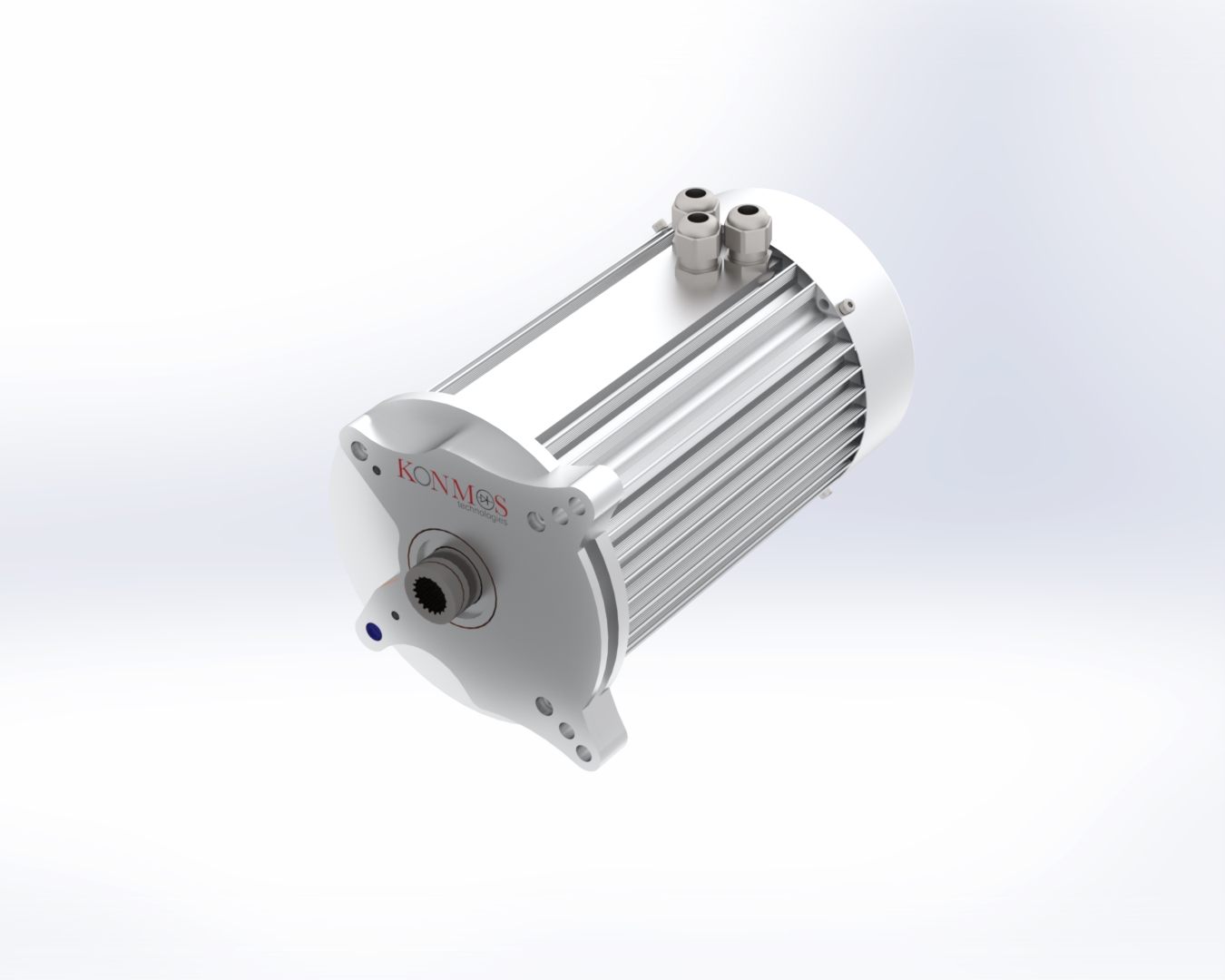

Mid-drive motors designed, developed and manufactured for on-road and off-road electric mobility.

| Specification | Range |

|---|---|

| Nominal Voltage | 48 V to 96 V |

| Nominal Power | 1 kW to 10 kW |

| Peak Torque | 10 Nm to 80 Nm |

| Maximum Speed | 8000 RPM |

| Ingress Protection | IP 67 |

Energy efficient and powerful electric vehicle motors are designed to ensure seamless driving experience and extended battery range along with mounting modularity and installation agility within vehicle.

AIS-041 compatible test setup for measurement of net power and maximum 30 minute power accurately confirms torque-speed, power-speed performance of motor.

Resolver (Sin/Cos) or Hall Sensor or Encoder configured motor ensures accurate detection of rotor position for precise torque-speed control and improved drive cycle efficiency.

Natural or forced air (tangential or rear-to-front) cooling arrangement enables faster and effective heat transfer for reliable and long life operation of motor.

Natural or forced air (tangential or rear-to-front) cooling arrangement enables faster and effective heat transfer for reliable and long life operation of motor.

PTC or NTC in stator winding safeguards motor against overheating due to undesirable load, stall conditions, sub-system component failure and catastrophic events.

| Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current | Max. Speed |

|---|---|---|---|---|---|---|---|

| IPMSM | 48 V | 5 kW | 19 Nm | 2500 RPM | 50 Nm | 400 Apeak | 6000 RPM |

| Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current | Max. Speed |

|---|---|---|---|---|---|---|---|

| IPMSM | 48 V | 3.1 kW | 9.9 Nm | 3000 RPM | 25 Nm | 250 Apeak | 6000 RPM |

| Max. Speed | Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current |

|---|---|---|---|---|---|---|---|

| IPMSM | 60 V | 4.0 kW | 15.2 Nm | 2500 RPM | 45 Nm | 300 Apeak | 4000 RPM |

| Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current | Max. Speed |

|---|---|---|---|---|---|---|---|

| IPMSM | 72 V | 4.0 kW | 19.0 Nm | 2000 RPM | 50 Nm | 250 Apeak | 4000 RPM |

| Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current | Max. Speed |

|---|---|---|---|---|---|---|---|

| IPMSM | 48 V | 2.0 kW | 6.3 Nm | 3000 RPM | 15 Nm | 150 Apeak | 6000 RPM |

| Motor | Voltage | Rated Power | Rated Torque | Rated Speed | Peak Torque | Peak Current | Max. Speed |

|---|---|---|---|---|---|---|---|

| IPMSM | 72 V | 7.5 kW | 23.8 Nm | 3000 RPM | 80 Nm | 500 Apeak | 5500 RPM |

Copyright © 2025 Designed by Technomantra